Kev Pabcuam Muaj Peev Xwm

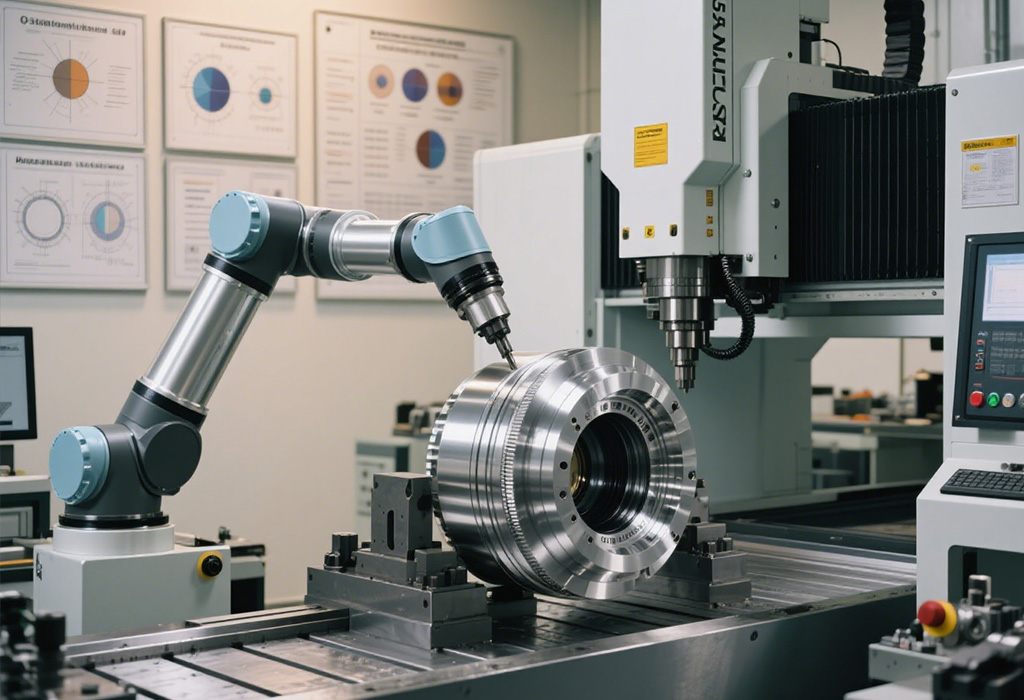

Table 1:CNC Machining Equipment & Technical Specifications.

| Qeb | Paub meej | Ntsiab Specifications |

| Hom tshuab | 5-axis CNC machining chaw (DMG MORI HSC 75 linear) | Ntau tshaj 60 units ntawm cov khoom siv |

| Khoom siv ntau yam | Hlau: Aluminium 6061/7075-T6, SS 304/316/17-4PH, Titanium Qib 5, Brass C36000 | Aerospace-qib cov ntaub ntawv (AMS 4928) |

| Kev Ua Ntau Yam | Max milling loj: 1500mm × 1000mm × 800mm | 5-sided machining nyob rau hauv ib qho kev teeb tsa |

| Precision kam rau ua | Machining kam rau ua: ± 0.005mm (5-axis) - ± 0.05mm (3-axis) | Kev ua raws li ISO 2768-mk |

| Tom qab ua tiav | Anodizing (Tim II / III lub tsho tawv tawv), hmoov txheej, Nickel chrome plating | ASTM B580 Plating txuj |

Daim Ntawv Thov Kev Lag Luam & Case Studies

Table 2:Tej Cheebtsam & Technical Achievements.

| Kev lag luam | Cov Cheebtsam | Technical Highlights |

| Aerospace | Turbine hniav hubs, tsaws iav brackets, Avionics vaj tse | 28% qhov hnyav txo los ntawm topology optimization FAA DO-160G kev co ua raws Ti-6Al-4V machined rau ± 0.01mm kam rau ua |

| Cov cuab yeej kho mob | Surgical forceps, Spinal implants, MRI-compatible components | Ti-6Al-4V acetabular khob nrog Ra 0.4μm tiav ISO 13485 Kev tsim cov chav huv huv 510 (k) cov ntaub ntawv txhawb nqa |

| Automotive (EV) | Roj teeb tais, Ncua caj npab, Hluav taws xob lub cev muaj zog vaj tse | Aluminium 6061-T6 tais 30% sib zog dua hlau 5-axis machined cua txias channel 10,000+ units / hli ntau lawm |

| Robotics | Harmonic tsav zog, Robotic caj npab pob qij txha, Sensor mounts | Gears nrog ± 0.003mm suab kam rau ua Carbon fiber inserts rau 40% backlash txo |

| Semiconductor | Wafer nqa, Precision fixtures, Nqus chamber Cheebtsam | 316L stainless hlau nrog Ra 0.8μm tiav ISO class 5 cleanroom sib dhos Cov txheej txheem tiv thaiv ESD |

Cov txheej txheem tsim khoom & Kev lees paub zoo

Tsim rau Manufacturability (DFM)

♦ 3D qauv tsom xam nrog SolidWorks/UG/NX.

♦ Tolerance stack-up simulation.

♦ Kev ua kom zoo ntawm cov khoom siv.

CNC Machining & In-Process Inspection

♦ 5-axis simultaneous machining rau complex geometry.

♦ Renishaw nyob rau hauv-lub voj voog soj ntsuam.

♦ Kev saib xyuas SPC tiag tiag.

Kev Tswj Xyuas Qhov Kawg

♦ Zeiss CMM tshuaj xyuas (± 0.002mm raug)./♦ Optical projector rau micro-features./♦ 100% kev kuaj pom pom & ua haujlwm.

Nqe & Sijhawm Lead

| Hom kev txiav txim | Ntau qhov ntau | Lub Sijhawm Lead | Nqe Factor |

| Prototyping | 1-50 units | 3-7 hnub | Khoom siv & complexity |

| Tsawg Volume | 50-1,000 units | 10-15 hnub | Batch efficiency |

| Kev tsim khoom loj | 1,000+ units | 20-45 hnub | Tooling amortization |

Daim ntawv pov thawj & Ua raws cai

Peb pab neeg txhawb nqa cov neeg siv khoom yeej ib txwm npaj los pab koj thoob plaws tag nrho cov txheej txheem.

ISO 9001: 2015 tau ntawv pov thawj

AS9100D rau aerospace Cheebtsam

ITAR sau npe