Comprehensive CNC tig peev xwm

Table 1:CNC Turning Equipment thiab Technical Specifications.

| Qeb | Paub meej | Ntsiab Specifications |

| Hom tshuab | CNC Slant - Lub txaj tig chaw: Doosan Puma 5100, Hyundai Wia Lynx 220LSY | Tag nrho cov cuab yeej tig: 30+ qib siab heev |

| Khoom siv ntau yam | Hlau: | Cov ntaub ntawv pov thawj: Cov ntaub ntawv qhia txog kev taug qab tag nrho muaj |

| Kev Ua Ntau Yam | Max tig txoj kab uas hla: 500mm | Nyob Tooling: Ua milling, drilling, thiab tapping cov haujlwm hauv ib qho kev teeb tsa |

| Precision kam rau ua | Roundness: ≤ 0.001 hli | Cov Khoom Siv Tshuaj Ntsuam Xyuas: Zeiss Contura CMM nrog qhov tseeb ntawm ± (1.5 + L / 350) μm |

| Post - Kev Ua Haujlwm | Nto Finishing: | Kev lag luam tus qauv: ASTM B580 (plating), Boeing BAC 5616 (anodizing) |

Daim Ntawv Thov Kev Lag Luam thiab Case Studies

Table 2:Tej Cheebtsam thiab Technical Achievements.

| Kev lag luam | Cov Cheebtsam | Technical Highlights |

| Aerospace | Turbine Shafts, tsaws iav Bolts Actuator Rods, Cav Mounting Studs | Khoom siv: Machined los ntawm Ti - 6Al - 4V nrog qhov ntev ntev ntawm ± 0.003 hli Nto tiav: Ua tiav Ra 0.4 μm ntawm cov kabmob tseem ceeb Kev Ua Raws Cai: Dhau FAA qaug zog thiab kev ntsuas kev ntxhov siab |

| Cov cuab yeej kho mob | Orthopedic Implants (Screws, Pins) Surgical Instrument Handles, Cannulas | Khoom siv: Kev kho mob - qib titanium (ASTM F136) nrog biocompatible nto kho Precision: Xov pitch kam rau ua nyob rau hauv ± 0.001 hli rau kev ruaj ntseg los ua ke Cleanroom Manufacturing: ISO 13485 ua raws li ib puag ncig tsim khoom |

| Automotive | Camshafts, Crankshafts Axle Shafts, Transmission Shafts | Khoom siv: 4140 alloy steel nrog quenched thiab tempered cua sov kho Efficiency: Txo lub sij hawm ntau lawm los ntawm 30% siv high-speed tig Ntim: Muaj peev xwm ua tau 10,000+ ncej hauv ib hlis |

| Roj & Roj | Downhole Tool Cheebtsam Valve Stems, Pump Shafts | Khoom siv: Corrosion - resistant alloys (Inconel, Hastelloy) Feature: Machined sib sib zog nqus threads nrog L / D piv> 15: 1 Kev Xeem: Dhau NACE MR0175 sulfide kev nyuaj siab corrosion kuaj |

| Electronics | Precision Connector Pins Thaum tshav kub kub Sink Spacers, Shafts rau me motors | Khoom siv: tooj dag nrog npib tsib xee plating rau conductivity thiab durability Precision: Txoj kab uas hla ntawm ± 0.002 hli rau nruj - haum daim ntaub ntawv Deg tiav: Electropolished rau Ra 0.8 μm rau kev txhim kho hluav taws xob tiv tauj |

Cov txheej txheem tsim khoom thiab kev ruaj ntseg zoo

Peb cov txheej txheem tsim khoom yog tsim los tswj cov qib siab tshaj plaws ntawm qhov tseeb thiab sib xws ntawm txhua theem.

Tsim Kev Tshawb Fawb thiab Kev Npaj Ua Haujlwm

Peb pib los ntawm kev ua tiav Kev Tsim Kho Kev Tsim Nyog (DFM) kev tshuaj xyuas siv cov software siab heev xws li SolidWorks thiab CAMWorks. Qhov no pab peb txhim kho cov cuab yeej cuab tam, xaiv cov ntaub ntawv tsim nyog tshaj plaws, thiab tsim cov khoom siv kho kom zoo los xyuas kom muaj kev ruaj ntseg thaum tuav lub tshuab.

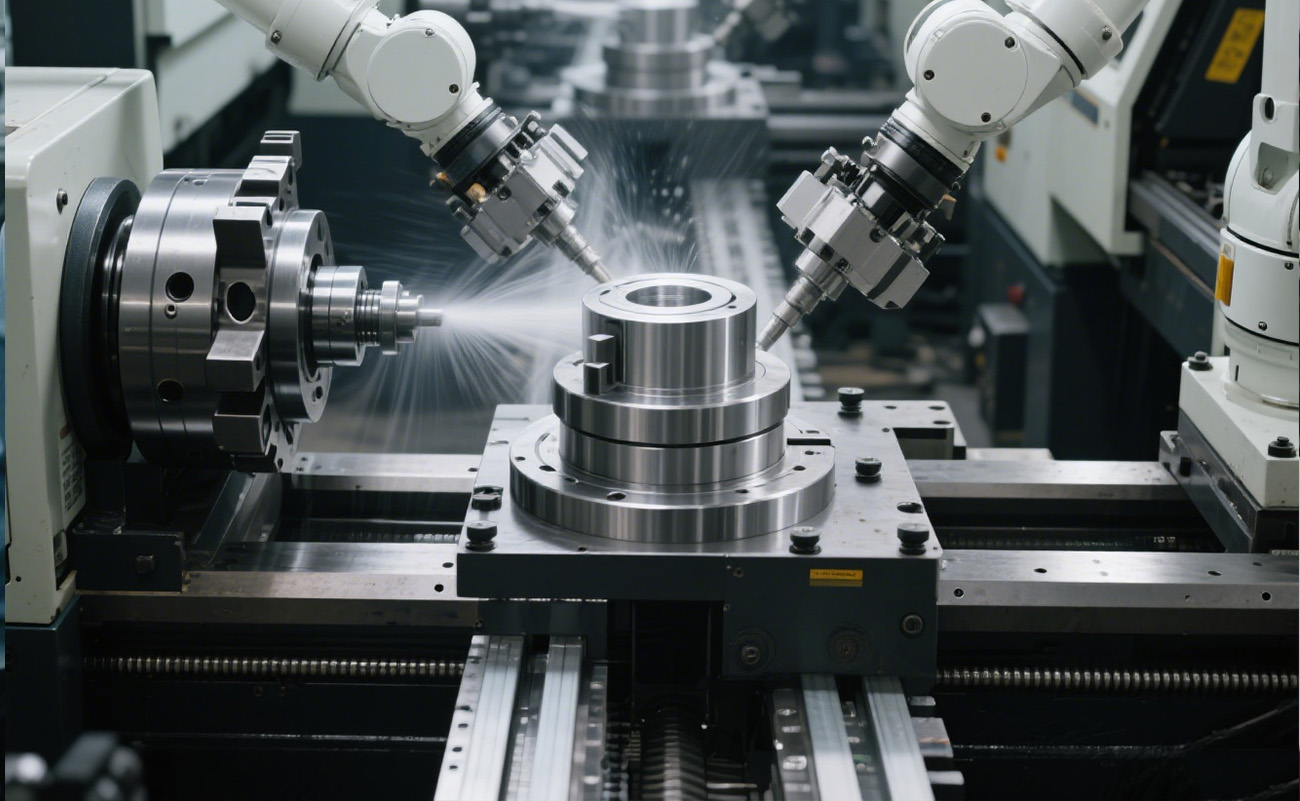

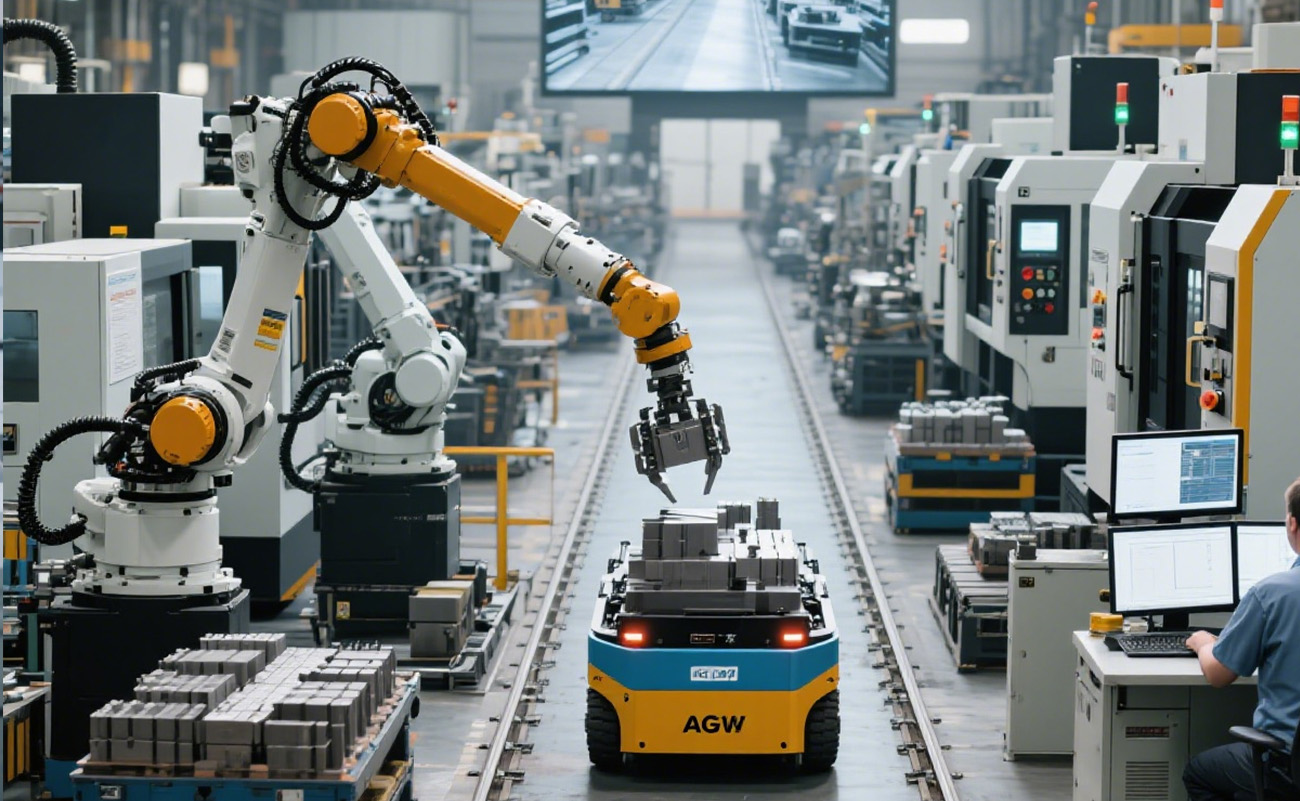

CNC tig thiab nyob rau hauv - txheej txheem saib xyuas

Peb cov tshuab machining automated, nruab nrog bar feeders thiab robotic loaders, pab kom tsis tu ncua ntawm cov khoom zoo tib yam. Renishaw nyob rau hauv - voj voog sojntsuam yog siv los ntsuas qhov ntev ntawm lub sijhawm, tso cai rau kev hloov kho tam sim. Kev Tswj Xyuas Txheej Txheem Txheej Txheem (SPC) cov txheej txheem yog siv los saib xyuas cov txheej txheem machining tseem ceeb, kom ntseeg tau tias muaj txiaj ntsig zoo thoob plaws hauv kev tsim khoom.

Kev soj ntsuam zaum kawg thiab kev tswj kom zoo

Txhua yam khoom siv tau ua cov txheej txheem tshuaj xyuas nruj. Peb siv lub Zeiss Contura Coordinate Measuring Machine (CMM) los ua kev ntsuas 3D, txheeb xyuas txhua qhov loj me nrog qhov raug siab. Kev kuaj pom 100% kuj tseem ua tau los kuaj xyuas qhov tsis xws luag, burrs, thiab ua tiav zoo. Rau cov khoom uas muaj cov kev xav tau tshwj xeeb, peb ua cov kev sim ua haujlwm ntxiv, xws li torque, hardness, thiab qaug zog.

Nqe thiab Sijhawm Lead

Table 2:Tej Cheebtsam thiab Technical Achievements.

| Hom kev txiav txim | Ntau qhov ntau | Lub Sijhawm Lead | Nqe Factor |

| Prototyping | 1-30 units | 3-5 hnub ua haujlwm | Tus nqi ntawm cov khoom siv, qhov nyuaj, thiab lub sijhawm teeb tsa |

| Tsawg Volume | 30-500 units | 7-12 hnub ua haujlwm | Batch loj, tooling xav tau |

| Kev tsim khoom loj | 500+ units | 15-30 hnub ua haujlwm | Kev tsim khoom ntim, cov khoom siv mus sij hawm ntev |

ISO 9001: 2015 Certified Quality Management System

AS9100D Ua raws li Aerospace Cheebtsam

ISO 13485 Ua raws li kev tsim khoom siv kho mob

RoHS / REACH Cov Khoom Siv Ua Raws Cai

Nqe thiab Sijhawm Lead

Npaj txhij coj koj qhov project mus rau lub neej? Hu rau peb pab neeg muag khoom paub txog hnub no.

Email:sales@xxyuprecision.com

Xov tooj:+86 - 755 - 27460192

Tsuas xa koj cov qauv 3D (STEP / IGES) lossis cov duab kos, thiab peb yuav muab cov ncauj lus kom ntxaws rau koj hauv 24 teev. Cia peb qhia koj vim li cas peb thiaj li nyiam CNC tig tus khub rau kev lag luam thoob ntiaj teb.