Coordinate Measuring Machines (CMMs) - 3D Measuring Powerhouses

Kuj tseem hu ua 3 - Dimensional Measuring Machines (CMMs), peb CMMs yog lub linchpin ntawm peb qhov kev tshuaj xyuas. Raws li tau piav qhia hauv daim duab hauv qab no, lawv yog cov cuab yeej siv tau zoo heev uas muaj peev xwm ntsuas ib feem qhov ntev nrog micron - qib precision.

CMMs pom ntau daim ntawv thov thoob plaws ntau hom kev lag luam, los ntawm aerospace mus rau kev kho mob. Hauv aerospace, lawv tau ua haujlwm los tshuaj xyuas cov khoom tseem ceeb xws li turbine blades, kom ntseeg tau tias txawm tias qhov ntev tshaj plaws nyob rau hauv qhov kev zam. Hauv kev kho mob, lawv txheeb xyuas qhov tseeb ntawm cov cuab yeej phais thiab cov khoom cog.

| Specification | Paub meej |

| Kev ntsuas ntau | [X] mm (Length) x [Y] mm (Width) x [Z] mm (Qhov siab), adaptable rau ntau qhov ntau thiab tsawg |

| Qhov tseeb | Txog li ± 0.001 hli, muab kev ntsuas qhov tseeb heev |

| Kev sojntsuam hom | Nruab nrog kov - ua rau kev sojntsuam rau kev ntsuas dav dav thiab kev sojntsuam sojntsuam rau qhov nyuaj ntawm qhov profile |

| Software Compatibility | Integrates nrog kev lag luam - ua metrology software rau cov ntaub ntawv tsom xam thiab qhia |

Coordinate Measuring Machines (CMMs) - 3D Measuring Powerhouses

Optical comparators yog qhov tseem ceeb rau kev soj ntsuam tsis sib cuag ntawm qhov chaw. Daim duab qhia txog lub hauv paus ntsiab lus ntawm kev ua haujlwm ntawm qhov sib piv ntawm qhov muag pom, qhov twg yog qhov loj dua thiab tso rau ntawm qhov screen rau kev ntsuas.

Cov no muaj txiaj ntsig tshwj xeeb hauv kev lag luam hluav taws xob, qhov twg cov khoom me me thiab tsis sib xws yuav tsum tau kuaj xyuas. Piv txwv li, lawv tuaj yeem siv los ntsuas qhov ntev ntawm micro-connectors lossis kev sib dhos ntawm cov kab hluav taws xob hauv Circuit Court. Hauv cov cuab yeej - thiab - tuag kev lag luam, optical comparors yog siv los xyuas qhov tseeb ntawm pwm thiab tuag.

| Specification | Paub meej |

| Magnification Range | Los ntawm [Min magnification] x rau [Max magnification] x, adjustable rau qhov sib txawv qhov ntau thiab tsawg thiab tshuaj xyuas |

| Duab daws teeb meem | High-resolution imaging, tso cai rau kom pom tseeb pom cov ntsiab lus zoo |

| Kev ntsuas qhov tseeb | ± 0.005 hli rau linear ntsuas, xyuas kom ntseeg tau cov txiaj ntsig |

| Illumination System | Nta kuj sib txawv - siv thiab ntau lub kaum sab xis illumination los txhim kho qhov pom kev |

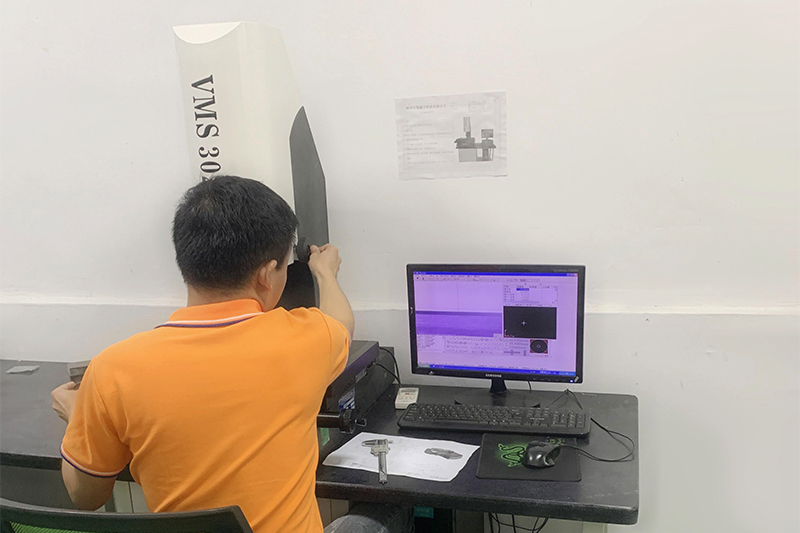

Digital Height Gauges - Precise Vertical Measurements (2.5D Projector).

Digital qhov siab ntsuas, feem ntau hu ua 2.5 - Dimensional Measuring Tools, ua lub luag haujlwm tseem ceeb hauv peb cov txheej txheem tshuaj xyuas. Cov duab hauv qab no qhia txog qhov ntsuas qhov siab digital hauv kev siv, ntsuas qhov siab ntawm lub workpiece nrog precision

Cov ntsuas no tau siv dav hauv kev tsim khoom los ntsuas qhov siab, qhov tob, thiab qib - qhov siab ntawm qhov chaw. Lawv yog cov tseem ceeb tshwj xeeb tshaj yog nyob rau hauv kev tsim cov precision - machined Cheebtsam, xws li cov nyob rau hauv lub tsheb thiab semiconductor industries.

| Specification | Paub meej |

| Kev ntsuas ntau | [Min qhov siab] - [Max qhov siab] mm, haum rau ntau yam ntawm qhov siab |

| Qhov tseeb | ± 0.01 hli, muab kev ntsuas ntsug ntsug |

| Zaub Hom | Cov zaub digital rau kev nyeem ntawv yooj yim thiab sau cov ntaub ntawv |

| Probe Options | Muaj nrog cov lus qhia sib txawv rau ntau hom nto |

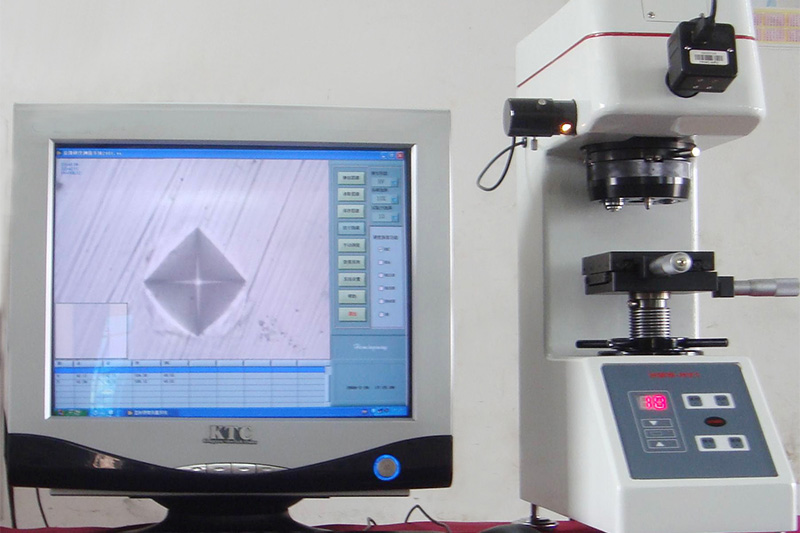

Hardness Testers

Kev sim hardness yog qhov tseem ceeb rau kev ua kom zoo ntawm cov khoom siv hauv peb cov txheej txheem machining. Cov duab hauv qab no qhia tau hais tias lub hardness tester siv los ntsuas qhov hardness ntawm cov qauv hlau.

Hauv kev lag luam hlau, kev ntsuas hardness pab tshawb xyuas qhov zoo ntawm cov khoom siv raw thiab cov khoom tiav. Piv txwv li, nyob rau hauv zus tau tej cov gears, hardness kuaj xyuas kom meej tias cov khoom muaj peev xwm tiv taus lub siab loads thiab stresses thaum lub sij hawm ua hauj lwm. Peb siv ntau hom hardness testers, xws li Rockwell, Brinell, thiab Vickers, kom haum raws li cov ntaub ntawv sib txawv thiab cov kev xeem.

| Specification | Paub meej |

| Hardness Scale Coverage | Rockwell: A, B, C nplai; Brinell: HBW nplai; Vickers: HV scale |

| Test Force Range | Adjustable kuaj rog kom haum cov khoom sib txawv hardness qib |

| Indenter Hom | Nruab nrog indenters tsim nyog rau txhua qhov hardness scale |

| Qhov tseeb | Kev ntsuas qhov tseeb, hauv ± [X] hardness units nyob ntawm qhov ntsuas |

Nto Roughness Testers

Nto roughness yog ib qho tseem ceeb hauv ntau daim ntawv thov, thiab peb cov neeg soj ntsuam qhov roughness yog tsim los ntsuas qhov ntsuas no kom raug. Daim duab qhia tau hais tias lub ntsej muag roughness tester nyob rau hauv kev siv, luam theej qhov saum npoo ntawm ib feem machined.

Hauv kev lag luam xws li tsheb thiab kev tsim khoom, qhov chaw roughness tuaj yeem cuam tshuam qhov kev ua tau zoo thiab kav ntev ntawm cov khoom. Piv txwv li, nyob rau hauv lub cav Cheebtsam, ib tug zoo nto tiav yuav txo tau kev sib txhuam thiab txhim khu kev ua tau zoo. Peb cov roughness testers tuaj yeem ntsuas ntau yam roughness tsis, xws li Ra (arithmetical txhais tau tias sib txawv ntawm qhov ntsuas profile) thiab Rz (qhov nruab nrab qhov siab ntawm tsib lub siab tshaj plaws thiab tsib qhov tob tshaj plaws hauv qhov ntsuas qhov ntev).

| Specification | Paub meej |

| Kev ntsuas ntau | Ra: [Min Ra tus nqi] - [Max Ra tus nqi] µm, haum rau ntau qhov chaw tiav |

| Sensor Hom | High-precision stylus sensors rau qhov tseeb qhov profile |

| Sampling Ntev | Adjustable sampling ntev kom tau raws li cov qauv kev lag luam sib txawv |

| Cov ntaub ntawv Output | Muaj peev xwm tso tawm cov ntaub ntawv nyob rau hauv ntau hom kom yooj yim kev koom ua ke nrog kev tswj xyuas zoo |

Microscopes

Microscopes yog qhov tseem ceeb rau kev tshuaj xyuas cov ntsiab lus feeb ntawm qhov chaw. Cov duab hauv qab no qhia tau hais tias lub tshuab ntsuas hluav taws xob tau siv los tshuaj xyuas ib feem ntawm qhov ntsuas siab

Hauv kev lag luam hluav taws xob thiab cov hniav nyiaj hniav kub, lub tshuab ntsuas hluav taws xob tau siv los tshuaj xyuas qhov zoo ntawm cov pob qij txha, qhov ua tiav ntawm cov hlau zoo nkauj, thiab kev ncaj ncees ntawm cov khoom siv micro. Lawv pab kom peb pab neeg soj ntsuam xyuas qhov tsis xws luag thiab qhov tsis zoo uas tsis pom ntawm qhov muag liab qab.

| Specification | Paub meej |

| Magnification Range | Los ntawm [Min magnification] x mus rau [Max magnification] x, tso cai rau kev soj ntsuam ntxaws ntawm ntau qib |

| Illumination System | Nruab nrog lub teeb ci LED kom pom tseeb ntawm cov qauv |

| Duab Capability | Qee cov qauv txhawb cov duab thaij rau cov ntaub ntawv thiab kev tshuaj xyuas |

| Kev kho kom haum | Precise focus adjustment for sharp imaging at different depths |

Micrometers

Micrometers yog precision - ntsuas cov cuab yeej siv los ntsuas qhov tseeb linear ntsuas. Cov duab hauv qab no qhia tau hais tias lub micrometer tau siv los ntsuas txoj kab uas hla ntawm ib feem cylindrical ..

Lawv feem ntau siv rau hauv machining kev ua haujlwm los ntsuas lub cheeb ntawm shafts, thickness ntawm cov ntaub ntawv, thiab qhov tob ntawm qhov. Micrometers paub txog lawv qhov raug siab thiab yog cov cuab yeej tseem ceeb hauv txhua qhov kev ua tau zoo - tsim ib puag ncig

| Specification | Paub meej |

| Kev ntsuas ntau | [Min ntsuas] - [Max ntsuas] mm, muaj nyob rau hauv ntau yam rau ntau yam kev siv |

| Qhov tseeb | ± 0.001 hli, muab cov kev ntsuas kab ncaj nraim |

| Anvil thiab Spindle Design | Precision - av anvils thiab spindles rau kev ntsuas zoo ib yam thiab txhim khu kev qha |

| Xauv Mechanism | Nruab nrog lub xauv mechanism los tuav qhov ntsuas hauv qhov chaw |

Calipers

Calipers yog cov cuab yeej ntsuas ntau yam uas tuaj yeem siv los ntsuas qhov ntsuas sab hauv, sab nraud, thiab qhov tob ntawm qhov chaw. Cov duab hauv qab no qhia tau hais tias lub caliper digital siv los ntsuas qhov dav ntawm ib feem.

Lawv tau dav siv nyob rau hauv ntau yam kev lag luam, los ntawm woodworking mus rau hlau fabrication. Calipers muab txoj hauv kev yooj yim thiab raug coj los ntsuas ceev thaum lub sijhawm tsim khoom.

| Specification | Paub meej |

| Magnification Range | Los ntawm [Min magnification] x mus rau [Max magnification] x, tso cai rau kev soj ntsuam ntxaws ntawm ntau qib |

| Illumination System | Nruab nrog lub teeb ci LED kom pom tseeb ntawm cov qauv |

| Duab Capability | Qee cov qauv txhawb cov duab thaij rau cov ntaub ntawv thiab kev tshuaj xyuas |

| Kev kho kom haum | Precise focus adjustment for sharp imaging at different depths |

Plug Gauges

Plug gauges yog siv los xyuas cov kab nruab nrab ntawm lub qhov thiab qhov bores. Cov duab hauv qab no qhia tau hais tias ib txheej ntawm cov ntsuas ntsuas tau siv los tshuaj xyuas lub qhov hauv qhov chaw ua haujlwm.

Hauv kev tsim khoom ntawm cov khoom xws li lub tog raj kheej lub tog raj kheej, lub tog raj kheej, thiab cov kav dej, ntsaws cov ntsuas kom paub meej tias cov kab uas hla sab hauv ua tau raws li qhov kev cia siab. Lawv yog cov cuab yeej yooj yim tab sis muaj txiaj ntsig zoo rau kev tswj xyuas qhov zoo hauv qhov - ntsig txog kev ntsuas

| Specification | Paub meej |

| Kev ntsuas Diameter Range | [Min txoj kab uas hla] - [Max txoj kab uas hla] mm, muaj nyob rau hauv ntau qhov ntau thiab tsawg kom phim qhov sib txawv diameters |

| Tolerance Chav Kawm | Tsim los rau cov chav kawm kam rau ua, xws li H7, H8, thiab lwm yam, rau kev txheeb xyuas qhov tseeb |

| Khoom siv | Ua los ntawm high-quality hardened steel rau durability thiab hnav tsis kam |

| Nto tiav | Smooth nto tiav los tiv thaiv kev puas tsuaj rau qhov raug tshuaj xyuas |